Where Did John Deere Get The Steel That Changed History?

No steel, no deal for John Deere.

The Illinois craftsman rocked world history with a mass-produced plow, but in the age of slim pickings and tough travel, where did Deere get his steel?

Two Johns

In 1804, Thomas Jefferson was re-elected president; Lewis and Clark began their transcontinental journey; Vice-President Aaron Burr fatally shot former Secretary of the Treasury Alexander Hamilton with a .54 caliber pistol; and the most influential blacksmith in U.S. history, John Deere, was born.

Deere arrived in an agricultural era when innovators sought a solution to the bane of farmers: soil stubbornly clinging to the plow blade. The agriculture metals of the day (cast iron or wrought iron) pitted in short time, allowing dirt to accumulate on blades—forcing farmers into frequent plow cleanings via wooden paddles.

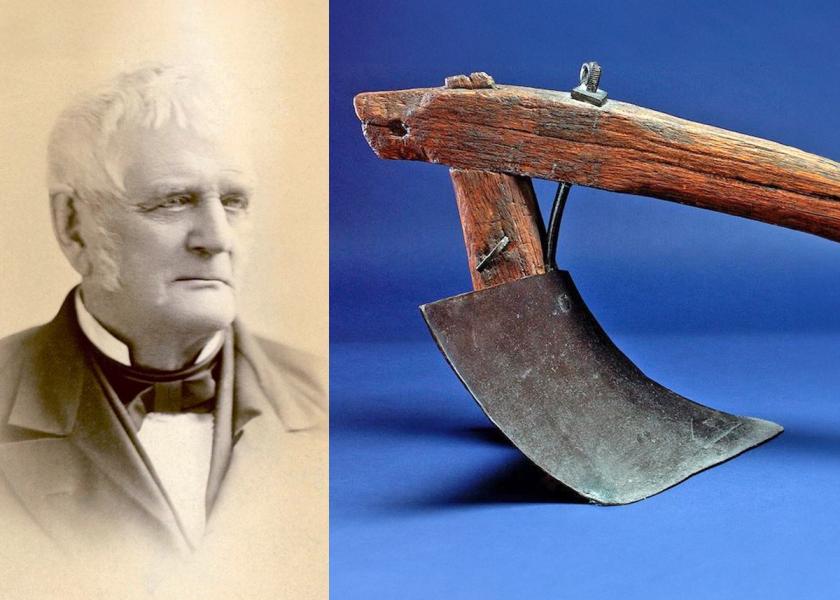

Credit for the first steel plow may belong to farming’s forgotten man: John Lane. Foreshadowing Deere, Lane was a transplant Illinois blacksmith in Homer Township (present-day suburb of Chicago). Lane’s antidote to the drag of rich soils was sleek, polished steel. In 1833, Lane obtained a steel sawmill blade and cut away three strips, welding two to the moldboard and one to the share of an iron plow. Lane began crafting steel plows according to individual demand, but he did not crank out plows for the masses.

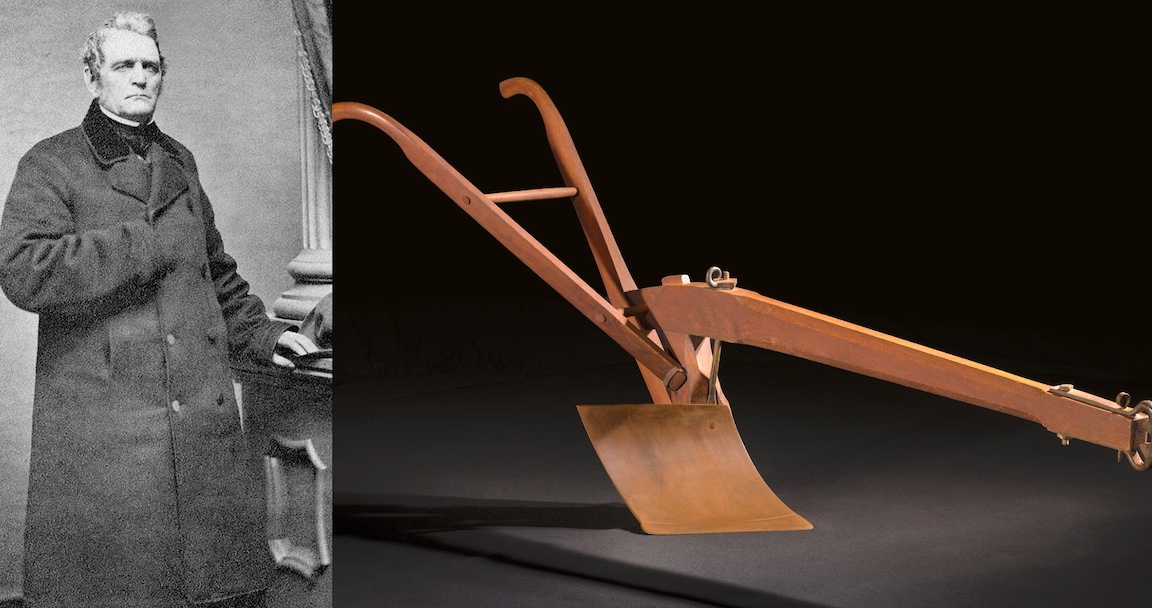

Enter a different John: Mr. Deere. Four years and roughly 100 miles west of Lane’s shop, Deere would shake history. Echoing Lane, Deere salvaged a broken bandsaw blade and carted it to his 26’-by-31’ blacksmith shop in Ogle County, Illinois.

Neil Dahlstrom, historian and archivist for Deere & Co., as well as author of Tractor Wars (along with The John Deere Story and Lincoln’s Wrath), describes Deere’s breakthrough. “He saw a broken steel blade at a local sawmill and had a moment of inspiration that he could find a solution to the problem. Deere asked for the broken blade and took it home, where he combined experience, ingenuity, and opportunity to build his steel plow.”

“He cut the blade down; heated and shaped it over the forge; and pounded it on an anvil. The plow also required wooden handles to be cut, and it’s unclear today whether the handles on his first plows were varnished or painted. He also made bolts and nuts, and a clevis on the front to hitch two horses. Later, he built wooden molds to help with shaping and uniformity.”

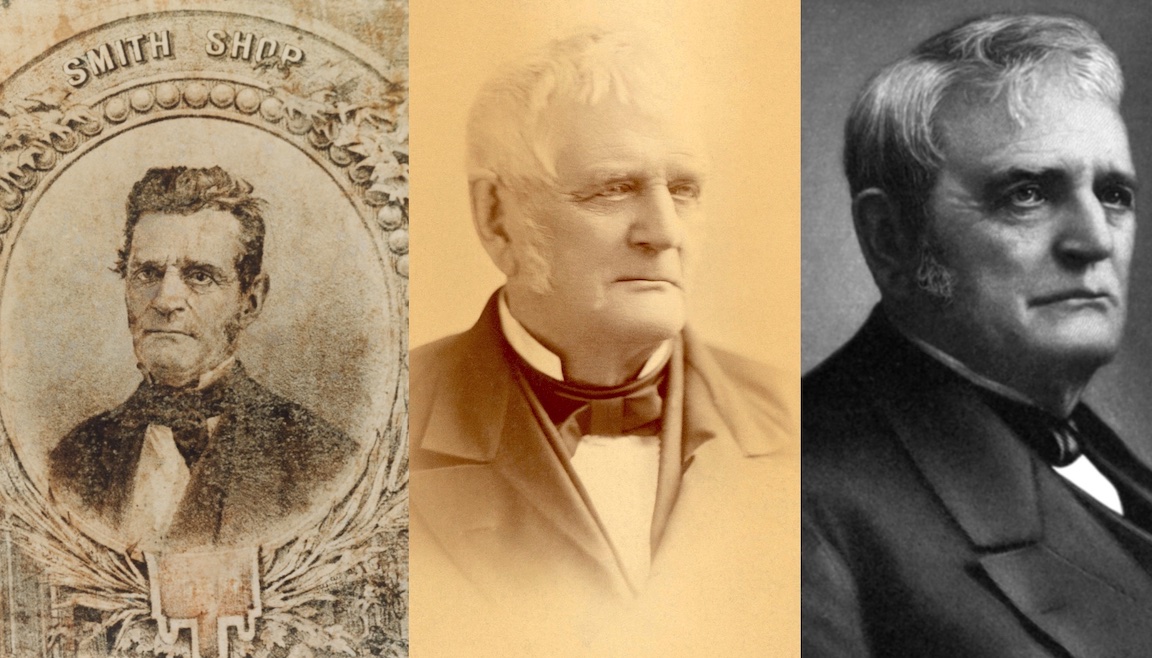

Swinging a hammer in strenuous labor over his lifetime, what was Deere’s physique? “One reference we have says he was about 6’ in height,” Dahlstrom notes. “His photos generally show a slender individual. However, there are only a handful of John Deere photos and most are from shoulder-up. I’ve seen a reference to fiery red hair, but that is only speculation.”

Initially sold for approximately $10-$12 apiece, the rapidity of Deere’s moldboard success is a testament of numbers. In 1837, Deere produced a single steel plow. In 1838, he bumped output to two plows. In 1839, Deere crafted 10 plows.

Feeding an insatiable customer base, Deere had a ticket to the moon, yet to go truly big-time, he needed an unfettered pipeline of a particular resource: steel.

Trickle to Flood

A Bowie knife preceded the plow—at least in terms of steel sourcing.

In the first half of the 19th century, Sheffield, England, was the king of global steel, supplying tool shops and blacksmiths across the U.S. In the 1830s, implements of every stripe, including Bowie knives emblematic of westward expansion, were often made in old England—specifically in Sheffield. By the 1850s, the genius of Henry Bessemer unleashed the Bessemer process and simplified the conversion of pig iron into steel—reducing steel costs by a factor of five, increasing volume, and ushering in mass amounts of steel for railways, bridges, and high-rise construction.

“Large scale production was a big challenge for Deere because there was a lack of steel availability in the U.S., especially in Grand Detour, Ill., which was at the edge of the frontier, especially 11 years before the Gold Rush,” Dahlstrom explains. “Acquiring steel was incredibly difficult.”

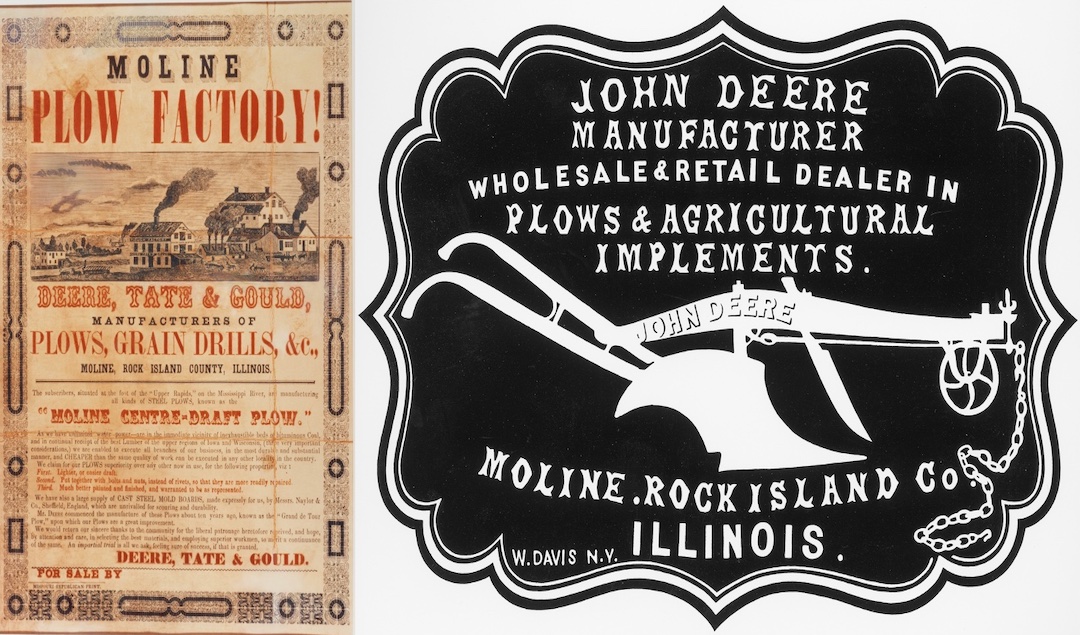

“At first, Deere imported steel from Sheffield, specifically from Naylor & Co. Naylor had a distributor in St. Louis, and Deere would travel to St. Louis and order steel, but we don’t know in what quantity.”

Significantly, when the railroad bypassed Grand Detour in 1843, Deere read the tea leaves and pulled stakes. He moved his operation 75 miles southwest to Moline, Ill., on the Mississippi River. By 1848, following construction of his new production facility, Deere pumped out 700 plows. A year later he built more than 2,000.

“By this point, Deere had a factory process where the work was piece-mealed. Among others, there was a grinding room for parts, a wooding room utilizing locally sourced white oak, and an assembly room,’ Dahlstrom describes. “Deere had a strong reputation for listening to customers and adjusting.”

As Deere ramped up production, settlers spilled west and farmed more ground, steadily increasing implement demand, i.e., Deere needed more steel.

By the mid-1800s, the U.S. was catching up with Sheffield and other steel hubs. In 1846, the first slab of rolled steel ever sold in the U.S. was sent from a Pittsburgh, Pa., manufacturer to Deere & Co. in Moline. “That was when Deere was able to truly utilize steel in plow production at scale,” Dahlstrom details. “In just over a decade, Deere turned from a blacksmith in a small shop to a plow manufacturer into a factory. He went to Pittsburgh, the heart of early U.S. steel production, and ordered the first ever rolled steel.”

Delivery was mainly via waterway. “It was all rivers and canals until you could go no further,” Dahlstrom notes. “Then it was mules and oxen and horses. The railroad came to Moline in the 1850s and that gave him rail or water options. Transportation was paramount and he made sure all his sales branches were built on river or railroad lines.”

Trickle to a flood: A mere decade after hauling home what was essentially sawmill scrap and making a single plow, Deere was ordering large volumes of steel and producing 1,000 plows per year.

Steel Wave

As Deere moved from a standard steel moldboard to plow variations, cultivators, harrows, riding plows, wagons, planters, and far more, did he consider steel production or steel investment to cut costs?

“There wasn’t any vertical integration with steel, but Deere did buy major timberland acres to source wood for manufacturing,” Dahlstrom says. “Prior to heavy mechanization, wood was a significant part of all Deere’s agriculture machinery.”

A handful of years shy of the steel moldboard’s 200th anniversary, what Deere questions remain to be answered for Dahlstrom?

“We don’t have any interviews of John Deere. I found a reference to an interview he gave in 1885 to a newspaper or magazine, a year before he died, and I’d love to find it. Rather than hear others, I’d love to hear Deere speak for himself.”

“One thing for certain,” Dahlstrom concludes. “Deere was ahead of his time in philanthropy, abolition, promoting education, church assistance, and the advancement of those around him.”

With impeccable timing, John Deere, 1804 to 1886, rode a steel wave and changed history.

For more from Chris Bennett (cbennett@farmjournal.com or 662-592-1106), see:

American Gothic: Farm Couple Nailed In Massive $9M Crop Insurance Fraud

Priceless Pistol Found After Decades Lost in Farmhouse Attic

Cottonmouth Farmer: The Insane Tale of a Buck-Wild Scheme to Corner the Snake Venom Market

Tractorcade: How an Epic Convoy and Legendary Farmer Army Shook Washington, D.C.